“Waste not, want not.” “Do more with less.”

We hear these mantras often, but how many organizations do you know that actually put them into practice?

This month, Profol attended its first annual meeting of the Composite Panel Association (CPA). The association’s commitment to the study of the sustainability of wood-based composite panel products and associated education of customers is far-reaching. As a manufacturer of polypropylene film for decorative surfaces, their messages hit close to home for us: you can build quality, durable and long-lasting wood-based products containing recycled wood fiber that stores carbon for decades.

- Composite panels are made from a variety of wood sources (sawmill residues, chips, sawdust, etc.), which ensures that the entire harvested tree is put to productive use with very little waste

- Sustainable forests provide millions of jobs and are carefully managed to provide an ongoing cycle of growth, harvest, and renewal that enables biodiversity, protects wildlife habitats, protects endangered plant species and improves local water quality.

Why is wood so important in maintaining healthy environments?

- Trees absorb carbon dioxide (CO2), and then they release oxygen (O2) back into the atmosphere and store excess carbon. Wood is 50% carbon.

- This sequestered carbon remains locked inside the wood – even after it becomes part of the built environment – until it is burned, decays or is placed in a landfill

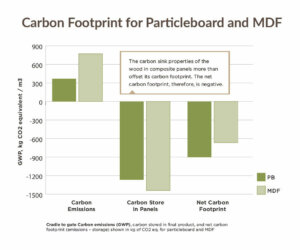

- Composite panels contain considerably more carbon than the amount released in their manufacture, transport and installation

Not just for the great outdoors

Since the average person spends the majority of their time indoors, air quality is critical to us all. For decades, the CPA has worked tirelessly with environmental organizations and federal and state agencies to develop emissions standards that are the most stringent in the world. These standards reduce emissions below what their levels would be in outdoor ambient air. Moreover, advances in formaldehyde-based resin technologies have reduced emissions to the equivalent of naturally occurring wood. New no-added formaldehyde technologies are also now available and widely in use.

How does Profol factor in?

The majority of decorative surface films produced at Profol are made of cast polypropylene, a recycled and recyclable plastic material. Unlike other plastic films, polymers like polypropylene contain no plasticizers, acids or heavy metal compounds. In addition, our films can be manufactured with the biodegradable EcoPure™ additive, which is shelf stable and will not begin to biodegrade until the film is in contact with microorganisms commonly only found in landfills.

Previously a lofty ideal, sustainability is now a reality. Profol is committed to supporting green practices and takes every opportunity to collaborate with those who feel the same. Let us know how we can help you, too.