Profol introduces Progano lightweight composite thermoplastic that replaces aluminum and other metals in formed components.

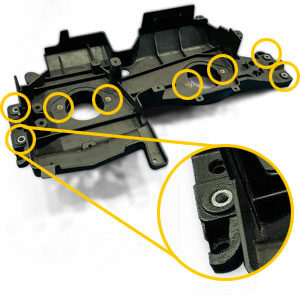

New Progano® lightweight composite organo sheet is a fiber-reinforced polymer made of glass fibers embedded in a polypropylene matrix. It is 30% lighter than aluminum and has similar strength as steel. Progano semi-finished sheet can be formed in many shapes using existing thermal presses and injection molding equipment. Functional elements such as threaded connections and inlays can be integrated directly into the production process, saving significant labor and handling costs.

This innovative material is used by automotive and other component manufacturers to increase strength, decrease weight and reduce production costs. The lightweight material also has applications in construction scaffolding boards, concrete casting boards and drainage covers. Progano sheet is completely recyclable for environmental sustainability.

“We are excited about the future prospects of the lightweight composites market, and seek to leverage our considerable knowledge about lean continuous mass manufacturing of thermoplastic materials,” said Dr. Philipp Schieferdecker, CEO and Managing Director of Profol.

Progano is constructed in a specialized two-step process. Profol uses proprietary techniques to produce unidirectional (UD) tape that has embedded glass fibers running in either 0 degree or 90 degree orientations. Profol then composites multiple layers of UD tape to form a strong and lightweight composite material (other configurations are also possible). Profol produces and distributes UD tape and Progano sheet in a wide variety of sizes to meet the needs of component manufacturers.

New manufacturing facility devoted to the production of Progano.

To meet market demand, Profol is investing more than 45 million dollars in a new manufacturing facility in Greiz, Germany, to produce both UD tape and Progano sheet. The plant is scheduled for start of production in 2020. At full operation, the new Progano manufacturing facility will employ 45 people and will grow to an annual capacity of more than 20,000 metric tons.

This plant will use a sequence of production processes strictly optimized for manufacturing efficiency to yield a unique product which allows for substitution of aluminum in high-volume automotive parts at significantly lower weight and cost.

To learn more about Progano sheet, contact Oliver Rüsseler at +49 (0) 8055 181 130 or oruesseler@profol.de.

About the company.

Since its beginning in 1980 as Profol GmbH (Halfing, Germany), the company has specialized in the production of high-quality cast polyolefin films. Since then, the environmentally friendly and versatile raw material cast polypropylene (CPP) has increasingly replaced other plastic film products. Polypropylene is odorless, tasteless and does not react with skin and mucous membrane. CPP films contain no plasticizers, acids or heavy metal compounds and are harmless to products and contact materials. Originally used mainly in the office supply industry, the material is increasingly gaining acceptance in the packaging, furniture and automotive industries.

Profol develops new product innovations based on CPP and other polyolefins, carries an extensive standard product line, and makes individual films to customer specifications. Profol supplies customers around the world through manufacturing sites in Europe, the Americas and Asia. With 26 production lines worldwide at its six production sites and approximately 500 employees, Profol has an annual capacity of over 120,000 metric tons of cast polyolefin film.

Profol actively promotes environmental protection and sustainability by striving to reduce the consumption of raw materials, producing with a minimum of energy (eg. through heat recovery) and using recyclable materials throughout the production process.